In the rapidly evolving landscape of consumer goods manufacturing, the importance of efficient packaging solutions cannot be overstated, particularly for diverse product types such as lotions and creams. According to a recent report by Mordor Intelligence, the global cosmetics packaging market is projected to reach USD 39.4 billion by 2025, driven by the increasing demand for innovative and user-friendly products.

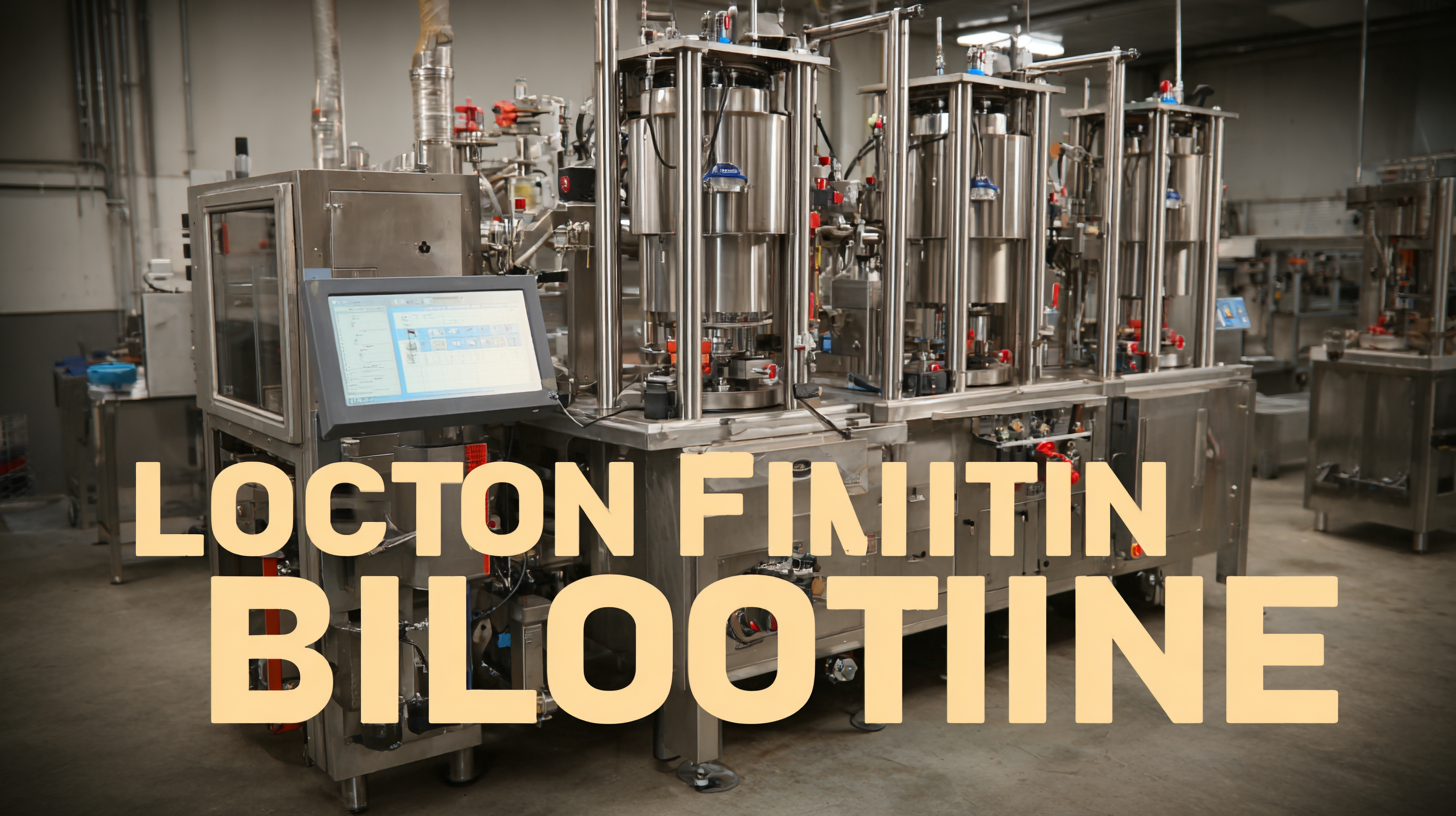

Central to this packaging efficiency is the Lotion Filling Machine, which streamlines the production process while ensuring high precision and reduced waste. These machines cater to a variety of formulations, adapting easily to various viscosities and container types, which enhances flexibility in product offerings. As companies seek to optimize their operations and meet consumer expectations, understanding the benefits of advanced lotion filling machines becomes crucial in maintaining a competitive edge in this dynamic market.

When investing in high-quality lotion filling machines, there are several key features that can dramatically enhance efficiency and product quality. First, consider the machine's accuracy. According to a market research report by

Advanced Market Analytics, precision in filling can reduce product waste by up to

20%, significantly cutting costs while ensuring consistent quality. Look for machines equipped with advanced filling technology that ensures a variance of less than 1% in volume dispensing.

Another essential feature is the adaptability to various product viscosities. Many industry studies, including findings from the International Journal of Advanced Manufacturing Technology, highlight the importance of flexibility in filling machines, especially for brands that offer a diverse range of products from lightweight lotions to thicker creams. Machines with adjustable parameters can accommodate these variations seamlessly.

Tips: Always prioritize user-friendly interfaces and automation features in your selection process. Machines that offer programmable settings can save valuable time during production. Additionally, consider the ease of cleaning and maintenance; machines designed with minimal crevices and quick-disassembly features will enhance hygiene and operational efficiency.

Choosing the right manufacturer for lotion filling machines is crucial for ensuring the efficiency and quality of your production line. With the global liquid filling machine market projected to grow from $6.82 billion in 2025 to $10.39 billion by 2032, a significant opportunity arises for businesses in the skincare and cosmetic sectors. Selecting a reputable manufacturer guarantees that you receive a machine that meets industry standards and caters to a range of product types, from serums to creams.

When evaluating potential manufacturers, consider their experience and expertise in producing lotion filling machines. Look for those that offer customizable solutions tailored to your specific product requirements. Additionally, inquire about the types of materials used in their machines to ensure durability and compliance with health regulations.

Tips: Always request case studies or testimonials from previous clients to gauge their satisfaction. Regular maintenance and support services are also essential; prioritize manufacturers who provide comprehensive after-sales support to keep your operations running smoothly. Finally, stay informed about the latest technological advancements in lotion filling to enhance your productivity and product quality.

This chart illustrates the production volume of various types of lotions, highlighting the significance of selecting effective lotion filling machines. Each product type has distinct production demands, emphasizing the need for choosing the right manufacturer for optimal results.

In the skincare industry, the demand for various product types such as creams, lotions, powders, and sprays necessitates specialized packaging solutions. Lotion filling machines, in particular, demonstrate significant versatility, catering to these diverse formulations. The comparative analysis of different lotion filling machine types reveals that not all machines are created equal; each is designed to meet specific requirements based on viscosity, container type, and production speed.

Automated lotion filling machines typically offer high efficiency and precision, essential for mass production. In contrast, semi-automatic systems allow for greater flexibility and are ideal for smaller batches or varying product formulations. Additionally, the choice of packaging type—whether tubes, bottles, or jars—can influence the filling technology employed. Understanding these distinctions is crucial for businesses seeking to optimize their manufacturing processes and ensure product integrity, ultimately contributing to a competitive edge in the rapidly evolving skincare market.

The landscape of manufacturing is continually evolving, and the integration of advanced lotion filling machines has emerged as a pivotal strategy for cost-effectiveness. According to a recent study published by MarketsandMarkets, the global liquid filling machine market is projected to reach $7.2 billion by 2026, growing at a CAGR of 6.9%. This growth underscores the increasing adoption of automated filling technologies, which not only enhance production efficiency but also significantly reduce labor costs.

Advanced filling machines are engineered to handle a variety of product types, including lotions, creams, and gels, with utmost precision. A technical report from Research and Markets highlights that companies utilizing these machines have seen a reduction in waste material by up to 20%. This is particularly beneficial for the cosmetics and personal care industries, where product margins are often razor-thin. The implementation of such technology not only minimizes material costs but also leads to faster turnaround times, allowing businesses to respond swiftly to market demands. As the industry continues to prioritize efficiency and sustainability, leveraging modern filling technology proves to be a smart investment for manufacturers aiming for long-term profitability.

In the fast-evolving landscape of the liquid packaging industry, optimizing production efficiency with lotion filling machines has never been more critical. As the global liquid filling machine market is projected to grow from $6.82 billion in 2025 to $10.39 billion by 2032, with a robust CAGR of 6.2%, embracing advanced filling technologies can significantly enhance operational efficiency.

This growth is largely driven by the increasing demand for high-quality cosmetic and personal care products, necessitating automated solutions that maximize output while ensuring precision and consistency in filling processes.

To achieve peak efficiency, manufacturers should adhere to best practices such as regular maintenance of machines, staff training, and adopting flexible systems that accommodate various product types, from lotions to serums.

The overall liquid packaging equipment market is anticipated to reach $8.2 billion in 2024, with a projected CAGR exceeding 5.8% from 2025 to 2034, highlighting the importance of integrating flexible filling solutions.

By leveraging these innovations, businesses can not only meet the growing consumer demands but also streamline their production lines, ensuring sustained profitability in a competitive market.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm