In today's highly competitive market, selecting the right packaging equipment can significantly impact efficiency, product safety, and overall operational costs. According to a report by Grand View Research, the global packaging machinery market is projected to reach USD 61.7 billion by 2025, driven by the increasing demand for automated packaging solutions in various industries. This trend underscores the importance of investing in suitable packaging equipment that aligns with your specific business needs. Whether you are looking to enhance productivity, reduce waste, or comply with regulatory standards, understanding the diverse options available—from semi-automatic to fully automatic systems—is crucial. By making informed decisions based on your product characteristics, production volume, and future scalability, businesses can improve their packaging processes and achieve a sustainable competitive edge.

When selecting the appropriate packaging equipment for your business, understanding your product characteristics is crucial. Different products have unique requirements based on their size, shape, fragility, and shelf life. For example, perishable items like fresh produce necessitate packaging that extends freshness, while fragile products like glassware require robust cushioning to prevent damage during transit. Therefore, evaluating the physical attributes of your products will help determine the kind of packaging solutions that will best protect and present them.

Additionally, considering factors such as production volume and automation needs is essential. High-output products may benefit from automated packaging solutions that enhance efficiency and reduce labor costs. In contrast, small-batch or artisanal products might be more suited to semi-automated or manual packaging systems. Understanding these variables not only ensures that your packaging equipment aligns with your product needs but also enhances your operational workflow and customer satisfaction. By thoroughly assessing these characteristics, businesses can make informed decisions that support their packaging objectives and overall growth.

When evaluating different types of packaging equipment available in the market, it's essential to understand the diverse options that cater to various business needs. According to a recent report by Grand View Research, the global packaging equipment market is projected to reach USD 63.39 billion by 2025, growing at a CAGR of 5.1%. This growth is driven by an increasing demand for efficient, cost-effective, and sustainable packaging solutions across industries.

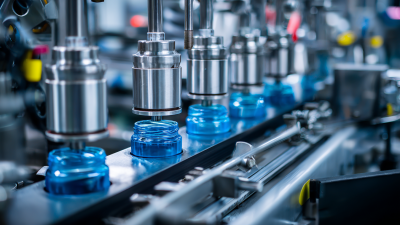

One primary category of packaging equipment is automated machinery, which has become increasingly popular due to its ability to enhance productivity and reduce labor costs. A survey conducted by Packaging World indicated that nearly 61% of companies are investing in automation technologies, demonstrating a shift towards streamlined operations. Additionally, specialized equipment such as shrink wrap machines and vacuum sealing devices cater to specific product requirements, ensuring freshness and optimization for different supply chains. Businesses must assess their production scale and product types before selecting the appropriate machinery, as the right choice can significantly impact operational efficiency and sustainability metrics.

| Equipment Type | Key Features | Advantages | Considerations |

|---|---|---|---|

| Automatic Filling Machines | High-speed filling, adjustable volume settings | Increased efficiency, reduced labor costs | Initial investment costs, maintenance requirements |

| Labeling Machines | Automatic label placement, various label types | Consistency, improved product presentation | Compatibility with container shapes and sizes |

| Shrink Wrapping Machines | Heat shrink technology, adjustable temperature | Tamper evidence, protection during shipping | Film compatibility and cost of materials |

| Cartoning Machines | Automatic box erection, product loading | High output, versatility with product sizes | Space requirements, setup time |

| Palletizing Machines | Robotic and conventional solutions, stack patterns | Labor savings, increased safety | Investment cost, complexity of operation |

When choosing packaging equipment, assessing budget constraints and potential return on investment (ROI) is crucial. According to a recent report by PMMI, the Association for Packaging and Processing Technologies, manufacturers often find that automated packaging solutions can lead to a 30% reduction in labor costs, making them an attractive option for businesses looking to enhance efficiency while adhering to budget limitations. This significant decrease in labor expenses can help offset initial capital investments in automated systems.

Furthermore, considering the lifespan and maintenance costs of packaging equipment is essential. A study by the Packaging Machinery Manufacturers Institute (PMMI) highlighted that well-maintained packaging machinery could provide an ROI of up to 200% over five years, emphasizing the importance of not just the purchase price but also the long-term operating costs. Businesses should carefully analyze projected production rates, downtimes, and maintenance schedules when evaluating equipment to ensure alignment with financial goals and operational needs. Taking these factors into account can help businesses make informed decisions that enhance both their packaging processes and their bottom line.

When selecting packaging equipment for your business, scalability should be a primary consideration. As your operations expand, the ability of your packaging solutions to adapt becomes crucial. Investing in machinery that can grow with your business ensures that you avoid the pitfalls of frequent equipment upgrades, which can disrupt production and incur additional costs. For instance, if current packaging machines have limitations in speed or versatility, they could hinder your ability to meet growing demand or diversify your product offerings.

Moreover, future growth isn't just about capacity; it's also about flexibility. The market can change rapidly, and consumer preferences may shift unexpectedly. Packaging equipment that is designed with scalability in mind can support various packaging styles, sizes, and materials. This adaptability not only allows businesses to respond to new trends but also enhances efficiency by reducing the need for specialized machinery tailored to specific products. By carefully evaluating scalability in your packaging solutions, you set your business on a path of sustainable growth and long-term success.

When selecting the right packaging equipment for your business needs, it's crucial to consider not only the functionality and efficiency of the machinery but also the vital components of maintenance, support, and training. Proper maintenance ensures optimal performance and longevity of the equipment, which can significantly affect productivity and operational costs. Implementing a routine maintenance schedule can prevent unexpected breakdowns and costly repairs, helping businesses maintain a smooth production flow.

In addition to maintenance, the availability of support from the equipment manufacturer is critical. Reliable customer service can make a difference, especially when technical issues arise that require immediate attention. Furthermore, investing in training for your staff is essential to maximize the benefits of any packaging solution. Well-trained employees will be more proficient in operating the equipment, understanding its features, and troubleshooting minor issues. This not only enhances workplace safety but also leads to increased efficiency, ultimately contributing to the success of the overall business.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm