In the fiercely competitive marketplace, first operating in compliance with global packaging standards should be regarded not only as a regulatory requirement but also as a very crucial element of any business strategy succeeding elsewhere. Increasingly aware of product safety and sustainability requirements, companies now look for smart solutions that help in packaging their products in compliance with rigorous international requirements. The most important thing is the choice of the packaging machine, so that profits through less downtime in its use may be made, costing less and the best quality packaging operation.

The selection of a suitable packaging machine must obey the specific requirements of your business, including types of products that are being packaged, production volume, and compliance with different packaging regulations. The choice between all existing packaging machines can be overwhelming and, yet, beyond this assessment discussion, one must decide which fits their operational requirements and remains compliant with global packaging standards. In this guide, the readers will find considerations and thoughts that will enable them to make better decisions in the field of packaging machinery, so as to improve their process and thereby improve market presence.

With businesses striving to meet international packaging standards, specific knowledge of federal regulations has become very important. The revised Express Delivery Regulations of China indicate the current drive for sustainable practices in the packaging industry. From June 1, the changes are expected to increase green development through reduction in packing and improvement of packing materials. Such a shift also influences how packaging logistics would be approached by the companies, besides setting new thresholds of sustainability which all players in the industry must put up with. Increased temperature-controlled packaging solutions demand that must especially pertain to pharmaceutical and health sectors is indicative of the need to adopt packaging technology that drives compliance. The pharmaceutical packaging market worldwide is expected to grow heavily over the next ten years, which means that compliance with international standards will be crucial to ensuring consumer safety and efficacy in packaging strategies. The right machinery should be used to comply with these evolving regulations to reap competitive advantage from ever-increasing consumer expectations for safe, environmentally friendly products. Companies also invest in technological advancements in the packaging technologies along with regulatory compliance to enhance efficiency and waste minimization. The water-based barrier technologies mark a considerable step forward in sustainable packaging solutions. They usher in the very great advances in the industry toward eco-friendly practices. It is as well an important aspect to be considered in this light of evolving changes that companies choose the right packaging machines compatible with global standards to usher in a more sustainable future of the packaging industry.

Choosing the right packaging machine for your company is based on an understanding of certain critical factors that tend to address the ever-changing needs of consumers. For example, one of Amcor's recent moves in China shows that people's packaging expectations have gone beyond the normal dimension of protection: Consumers of today are interested in functionality, convenience, safety, and appearance. As a result, such considerations make it imperative to think well when selecting packaging machinery that is able to satisfy all these different demands.

One vital area would be adaptability of the machine to different product types, which means packaging designs. In the event that one requires an eye-catching packaging due to the growth of e-commerce, then one needs to invest in a piece of machinery that can handle different formats or materials with ease. Cleared and speed are also important; as fast as consumer choices change, so demand on production machines for getting in those types at times becomes very high without sacrificing quality.

Sustainability is another of essential drivers towards which one would need to lean on methods one selects for packaging machinery. For instance, Amcor's innovative advancements have included those with sustainable practice and equipment that can significantly reduce waste as well as allow the use of eco-friendly materials. Such machines could make a great image about the brand but would also get a wide appeal to the environmentally conscious consumer. Thus, an understanding of these three main features' adaptability, efficiency, and sustainability will empower manufacturers to make appropriate decisions in their packaging processes, which will ultimately ensure that they remain successful in a competitive marketplace.

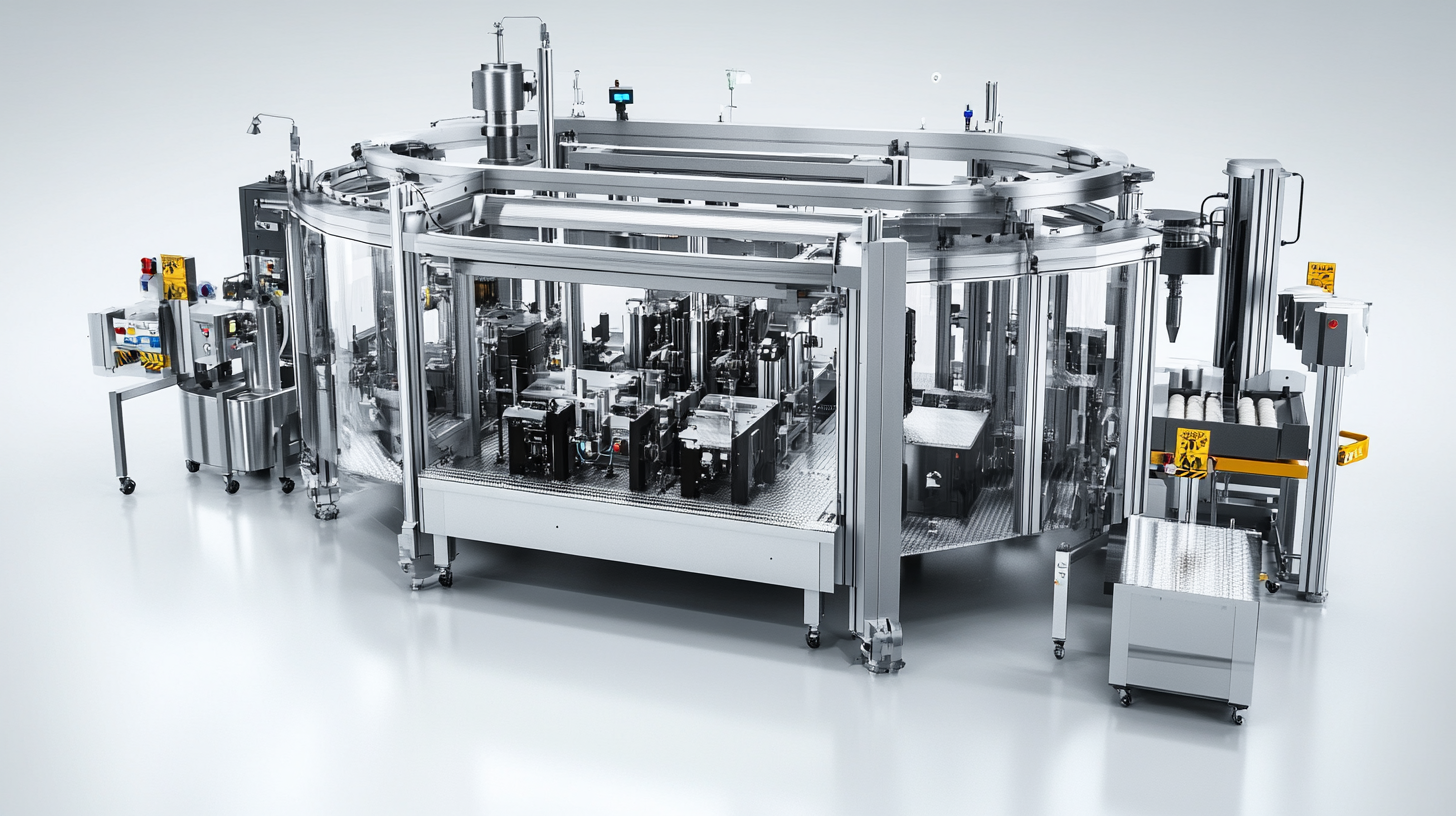

When selecting the right packaging machines for your business, the first step is identifying the performance and efficiency evaluation parameters. As per a recent report issued by Smithers Pira, the global market for packaging machinery is expected to go up to $50 billion in 2025 with a strong focus on automated technologies and those which improve productivity. There is growing awareness among businesses regarding the relationship between the capabilities of their packaging equipment and operation costs.

Some of the performance measures of packaging machines include throughput, downtime, and maintenance requirements. The machine with the highest throughput means much less time converting raw materials into finished products, resulting in greater throughput. According to studies by the International Society of Automation, advanced processing and packaging technologies can lead to improvements in production cost efficiencies of up to 30%. Therefore, companies must also select appropriate machines which meet existing production requirements yet hold the flexibility to meet evolving future demands.

Energy consumption and waste reduction also influence efficiency in packaging machines. Energy-efficient packaging machines will reduce total consumption between 15-20%- U.S. Department of Energy cost-effective investment in energy-efficient technologies. Investment in energy-efficient technologies will lead to reduced operating costs and caring for future sustainability initiatives that are becoming psychological factors for consumers. With all these aspects and measures of performance and efficiency, producers will be confident that they invest in the right packaging machines to grow and be sustainable.

It is not only input but also a cost structure that plays importance for budgeted packaging machinery for businesses navigating various complexities of global packaging norms. Various industries have different costs and returns; for example, in cotton production, costs and returns vary significantly over regions, and so does the packaging industry. For instance, some advanced packaging machine may be costlier in the initial investment but can bring in high return on investment in terms of efficiency and quality over the years.

Now, another key area that is segmentation in budgets is not only initial capital costs of packaging machinery but also variable costs like maintenance, labor, and material. The emergence of automated solutions forms a different concept in operation costs, which needs to be identified against output gains. Some companies have reports such that they are leveraging the potential of automation technologies in streamlining operations associated with logistics-creating affordances for labor savings and better service speed and consistency.

Environmental factors are also becoming a growing feature in budgets. With the increasing need for sustainable packaged solutions, ensuring that machinery buys into such capability can favorably position companies in the market and, over time, result in returns as a cost reduction on compliance and waste. Budgetary contrivances are meant to align budget strategy with the emerging trend, the need to spend on packaging machinery, not only as an expenditure but as a strategic and sustainable growth and competitiveness investment in the global market.

Future-proofing operations with cutting-edge technologies has become an imperative for businesses in this fast-changing packaging world. As was discussed at the AI and Network Transformation Seminar, the implementation of AI in different areas—particularly innovations in operations and process optimization—is a game-changing development that all packaging operations are going to have to confront. These investments in AI-driven technologies will cut costs, streamline processes, and ultimately make companies far more productive—all important points to consider for companies trying to keep their shoes ahead in a very global market.

According to a Smithers Pira report, more than 4% shall be added to the global packaging machinery market per annum until approximately $50 billion in 2024. This growth is due to the increasing interest in packaging that is effective and sustainable. By deploying advanced technologies such as artificial intelligence, companies can use predictive analytics to obtain better forecasts of packaging demands and fine-address inventory management while reducing waste-all while meeting consumer demand, as well as global packaging standards.

Companies such as McDonald's China are already going through their digital transformation by adopting significant technology players like Microsoft to bring about digital innovations into their packaging and systems. Such developments complement the significance of synchronizing packaging operations with technological developments to render such operations flexible in a more dynamic market environment. These technologies will serve well not just to address compliance issues but also ensure a sustainable future for packaging.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm