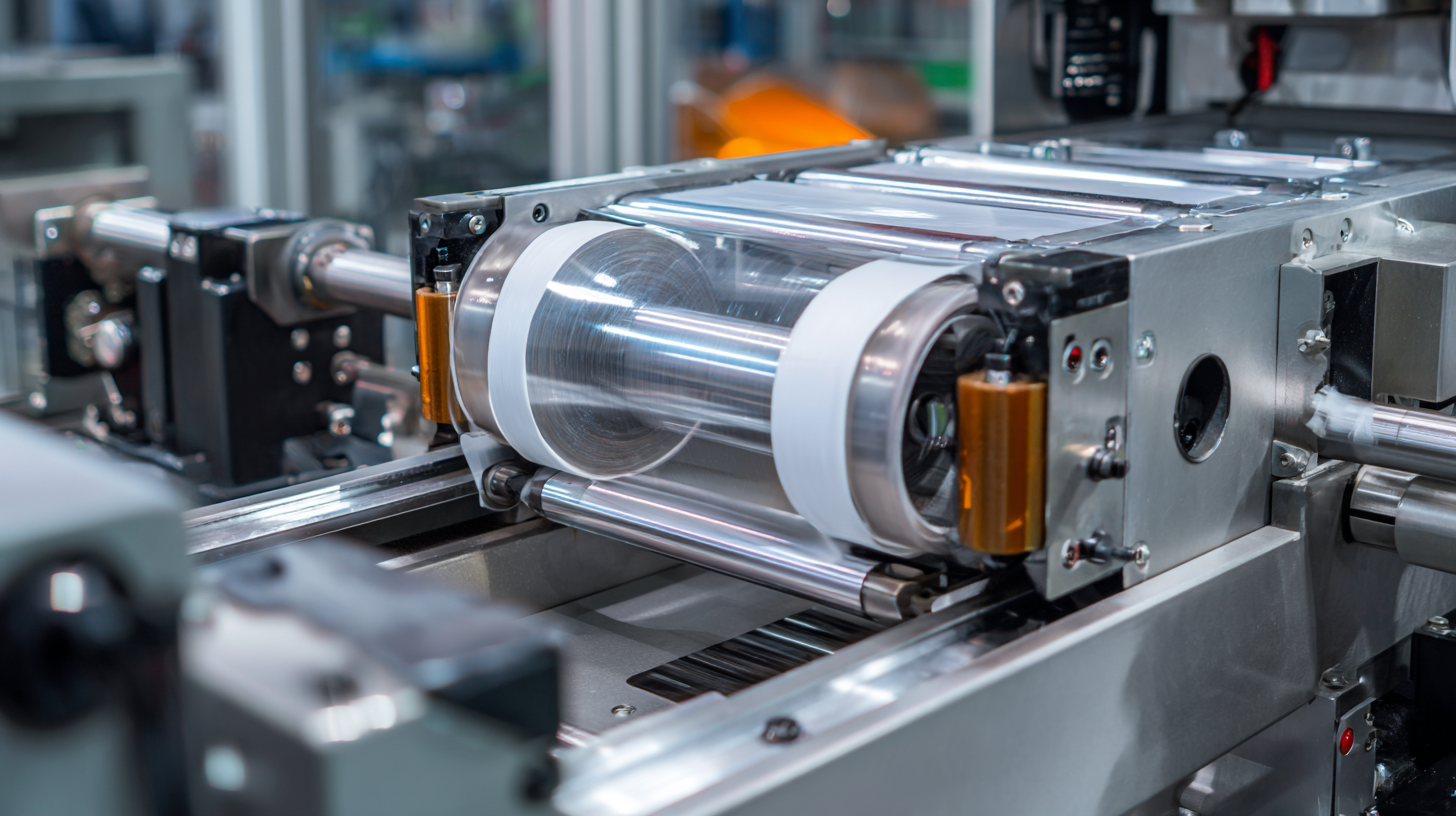

In today’s competitive market, choosing the right Packaging Machine is crucial for business success. According to a report by Markets and Markets, the global packaging machinery market is projected to reach USD 45.4 billion by 2025, growing at a CAGR of 3.7%. This growth underscores the vital role that efficient packaging plays in enhancing operational productivity and minimizing costs. With a diverse range of packaging solutions available—ranging from automated systems to semi-automatic machines—understanding the technical specifications and the digital capabilities of these machines can significantly impact the efficiency and effectiveness of packaging processes.

Business owners must consider factors such as machine versatility, speed, and compatibility with various packaging materials to ensure they are investing in a solution that aligns with their operational goals. In this blog, we will unveil five secrets to selecting the optimal Packaging Machine that can contribute to your business’s long-term success.

When investing in packaging machines, after-sales service can significantly impact your business's long-term success. One of the key factors to evaluate is the availability of technical support. A reliable supplier should offer prompt assistance, ensuring any operational issues are quickly resolved to minimize downtime. Your team should have access to knowledgeable professionals who can provide troubleshooting and guidance, which can keep your production line running smoothly.

Another critical aspect to consider is the warranty and service agreements provided by the manufacturer. A comprehensive warranty can save your business significant expenses in the event of a malfunction, while well-defined service agreements can help you understand the level of support you can expect. Look for suppliers who offer flexible plans that can be tailored to your operational needs, ensuring you are not left without assistance when it's most needed. Additionally, check if they provide training services as part of their after-sales support, empowering your employees with the skills to operate and maintain the equipment efficiently.

When selecting the right packaging machine for your business, understanding the maintenance costs is crucial to ensure long-term success. Maintenance costs can significantly impact your overall budget, which is why it’s essential to consider both the initial purchase price and the ongoing operational expenses. According to industry statistics, maintenance can account for as much as 10-20% of a machine's total cost over its lifespan. This means that a seemingly affordable machine can become a financial burden if it requires frequent repairs or has high operational inefficiencies.

In addition to direct maintenance costs, businesses should also factor in downtime and the potential loss of productivity when a machine is out of service. Frequent maintenance may lead to interruptions in production schedules, which can ultimately affect your bottom line. Investing in a high-quality packaging machine with a solid maintenance track record can mitigate these risks. Companies should assess warranty options, service availability, and the manufacturer's reputation for support. By prioritizing maintenance considerations in the purchasing process, businesses can make informed decisions that contribute to sustainable growth and operational efficiency.

| Cost Factor | Estimated Cost ($) | Frequency of Maintenance | Impact on Downtime (%) |

|---|---|---|---|

| Routine Maintenance | 500 | Monthly | 5 |

| Parts Replacement | 1500 | Annually | 10 |

| Emergency Repairs | 2500 | As Needed | 30 |

| Training Costs | 1000 | Biannually | 2 |

| Software Updates | 750 | Annually | 1 |

In today's fast-paced industrial landscape, digital innovations in packaging play a crucial role in enhancing operational efficiency and cost-effectiveness. Businesses are increasingly turning to smart packaging solutions that leverage advanced technologies such as IoT, AI, and automation. These innovations enable real-time monitoring of production processes, allowing companies to optimize workflows, reduce downtime, and ensure quality control. By integrating these digital tools, businesses can respond quickly to market changes and customer demands while maintaining high production standards.

Moreover, the deployment of data analytics in packaging operations empowers businesses to make informed decisions. By analyzing patterns and trends, companies can predict demand fluctuations, adjust their production levels, and minimize waste. Additionally, automated packaging machines equipped with machine learning capabilities can learn from previous operations, improving their efficiency over time. This proactive approach not only reduces operational costs but also enhances the overall sustainability of packaging processes, ultimately leading to increased profitability and market competitiveness.

When selecting the right packaging machine for your business, it’s essential to understand how quality packaging equipment impacts long-term ROI and profit margins. A well-chosen packaging machine not only enhances your product's shelf appeal but also streamlines production processes, ultimately leading to increased efficiency and reduced costs.

When selecting the right packaging machine for your business, it’s essential to understand how quality packaging equipment impacts long-term ROI and profit margins. A well-chosen packaging machine not only enhances your product's shelf appeal but also streamlines production processes, ultimately leading to increased efficiency and reduced costs.

Tip: Always consider the total cost of ownership when investing in packaging machinery. This includes not just the initial purchase price, but also factors like maintenance, energy consumption, and potential downtime. A more expensive, high-quality machine may offer better durability and efficiency, leading to greater savings over time.

Another critical aspect to consider is the adaptability of the packaging machine. The market is constantly evolving, and being able to swiftly adjust your packaging line to accommodate new products or changes in consumer preferences can significantly affect your competitiveness.

Tip: Evaluate machinery that offers flexibility in packaging formats and sizes. Investing in versatile equipment enables you to respond swiftly to market demands, ensuring that your business remains relevant and profitable in a changing landscape.

When selecting the right packaging machine for your industry needs, it is crucial to consider several factors that can significantly impact your efficiency and product quality. First and foremost, assess the specific requirements of your product. This includes size, shape, and packaging material. A machine that can handle various package types can provide the flexibility your business might need in the future.

Another important tip is to evaluate the machine's speed and output capacity. If your production demands are high, ensure that the packaging machine can keep up without compromising quality. Additionally, consider the ease of operation and maintenance. A user-friendly machine will not only reduce training time for employees but can also minimize downtime due to technical issues.

Finally, it's wise to investigate the manufacturer's reputation and service support. Choose a supplier that offers reliable customer service and support, as well as maintenance plans. This will help ensure that your packaging operations run smoothly and efficiently, contributing to your overall business success.

Headquarters

2980 Scott St, Vista, CA 92081

Phone: (760) 734-4177

Fax: (760) 734-4188

Open: 8:00 am – 4:30 pm

Texas

8051 Jetstar Dr #175 Irving, TX 75063

Phone: (972) 915-6888

Fax: (972) 915-6999

Open: 8:00 am – 4:30 pm

Florida

14231 Jetport Loop. #1 Fort Myers, FL 33913

Phone: (239) 225-4020

Fax: (239) 225-4024

Open: 8:00 am – 4:30 pm